Pneumatic three-way threaded ball valve, Q614F,Q615F

气动内螺纹三通球阀Q614F/Q615FPneumatic three-way threaded ball valve, Q614F,Q615F 气动内螺纹...

气动内螺纹三通球阀Q614F/Q615FPneumatic three-way threaded ball valve, Q614F,Q615F 气动内螺纹...

气动内螺纹三通球阀Q614F/Q615F

Pneumatic three-way threaded ball valve, Q614F,Q615F

气动内螺纹三通球阀Q614F/Q615F

Stem Sealing with Anti-Blowout Design

The valve stem adopts a blowout-proof sealing system with a two-stage sealing mechanism:

Primary Sealing

A tapered stem cooperates with a tapered stem seal to effectively prevent medium leakage during stem rotation.

Even under abnormal pressure surges, the sealing remains reliable.

Secondary Sealing

A set of V-shaped packing rings expands outward when compressed, forming an additional leak-proof barrier.

Automatic Wear Compensation

A Belleville spring provides preload compression, automatically compensating for wear in the packing and stem seal.

Secure Sealing System

The stem nut compresses the entire sealing assembly to prevent leakage.

A lock washer secures the stem nut to prevent loosening.

Pneumatic Internal Thread Three-Way Ball Valve Q614F/Q615F

Overview

The pneumatic internal thread (butt-weld) three-way ball valve consists of a double/single-acting pneumatic piston actuator and an internal thread (butt-weld) ball valve.

Key Features:

Valve Body Options: One-piece, two-piece, or three-piece construction.

Elastic Seat Seal: Ensures reliable sealing and smooth operation.

Bottom-Mounted Stem with Backseat Seal: Prevents stem ejection under abnormal cavity pressure.

Low-Friction Actuator:

Bearing sleeve made of low-friction material.

Hard anodized cylinder surfaces for corrosion resistance and extended service life.

Stable Performance: Widely used in petrochemical, metallurgy, power, light industry, and pharmaceutical sectors.

Working Principle

When the pneumatic actuator is connected to the power supply and air source, air enters cylinder A (or B) through pipeline A/B, driving the piston to rotate the shaft and ball by 90°.

Visual Indicators:

Top-mounted position indicator: Green mark ("OPEN") shows valve is open.

Limit switch signal:

Green light = Open

Red light = Closed

Positioner: Adjusts flow rate in the pipeline.

Note: This design ensures high sealing reliability, blowout-proof safety, and long-term durability under demanding industrial conditions.

| 气动执行器 | 型号 | QW-TZ精小型系列、AT单作用系列 |

| 控制形式 | 双作用/单作用 | |

| 作用形式 | 切断/调节 | |

| 气源压力 | 0.4 ~ 0.8 MPa | |

| 最大回转角度 | 90°~92° | |

| 回信器 | AC220V AC110V DC24V | |

| 控制信号 | 电信号:0~0Ma 4 ~20Ma 气信号:0.02 ~0.1 MPa | |

| 控制气源 | 洁净、干燥压缩空气 | |

| 工作温度 | -20℃ ~ +90℃ |

| 零件名称 | 阀体 | 球芯 | 阀座 | 阀杆 | 填料 |

| Q611F-16Q611F-25 | 304 | 0Cr18Ni9 | 增强聚四氟乙烯 | 0Cr18Ni9 | 增强聚四氟乙烯 |

| 316 | 0Cr17Ni12Mo2 | 增强聚四氟乙烯 | 0Cr17Ni12Mo2 | 增强聚四氟乙烯 |

| 型 号 | 公称压力PN(MPa) | 试验压力Ps(MPa) | 工作温度(℃) | 适用介质 | |

| 壳体 | 密封 | ||||

| Q611F-16P(R) | 1.6 | 2.4 | 1.76 | -20~150 | 水、蒸汽、油品、酸类 |

| Q611F-25P(R) | 2.5 | 3.75 | 2.75 | ||

| Q611F-40P(R) | 4.0 | 6.0 | 4.4 | ||

| 零件名称 | 缸体 | 端盖 | 活塞 | 轴 | O型圈 | 螺栓 |

| QW-TZAT | 铝合金型材硬质阳极氧化 | 压铸铝合金环氧树脂喷涂 | 压铸铝 | 钢镀镍磷合金 | NBR | SUS304 |

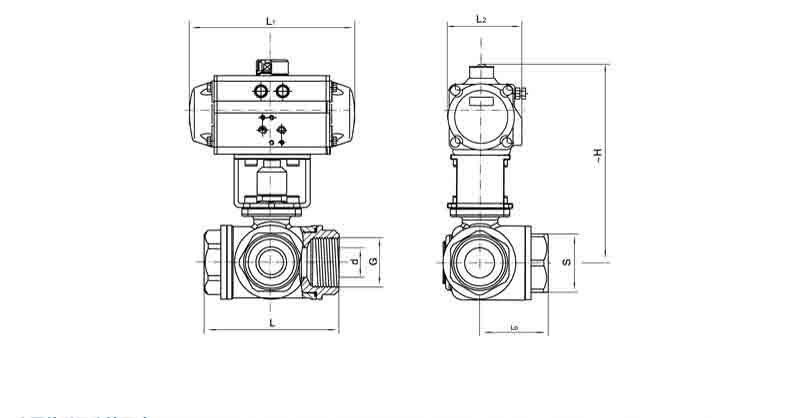

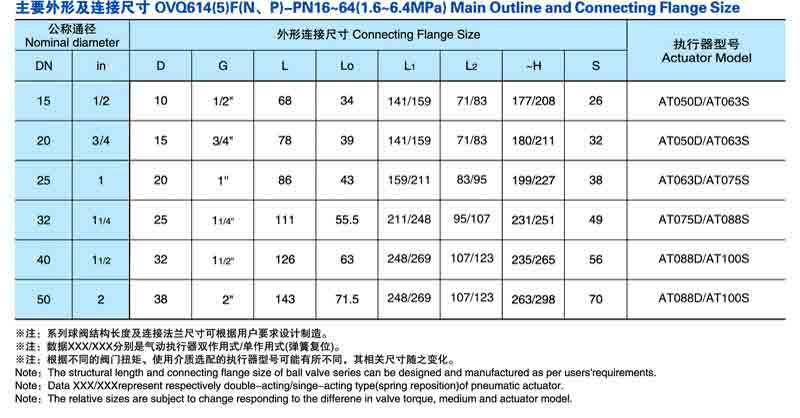

| 公称通径 DN(mm) | 外型尺寸 | |||||||

| 16~6.4Mpa | ||||||||

| G | L | LO | H | L1 | L2 | S | d | |

| 15 | 1/2″ | 68 | 34 | 130 | 140 | 62 | 26 | 10 |

| 20 | 3/4″ | 78 | 39 | 135 | 140 | 62 | 32 | 15 |

| 25 | 1″ | 86 | 43 | 139 | 140 | 62 | 38 | 20 |

| 32 | 1-1/4″ | 111 | 55.5 | 158 | 164 | 75 | 49 | 25 |

| 40 | 1-1/2″ | 126 | 63 | 165 | 164 | 75 | 56 | 32 |

| 50 | 2″ | 143 | 71.5 | 202 | 190 | 91 | 78 | 38 |

Flow Direction Principles of Three-Way Ball Valves

Three-way ball valves are classified into L-type and T-type, with distinct flow path configurations (see diagram below).

L-Type Three-Way Ball Valve

Designed for flow direction switching.

Connects two perpendicular pipelines while blocking the third.

Typical applications: diverting flow between two alternate paths.

T-Type Three-Way Ball Valve

Suitable for flow splitting, merging, or directional switching.

The T-shaped bore allows:

All three ports to interconnect (full flow distribution).

Any two ports to connect while isolating the third.

Standard design: Dual-seat structure (optional four-seat configuration upon request).

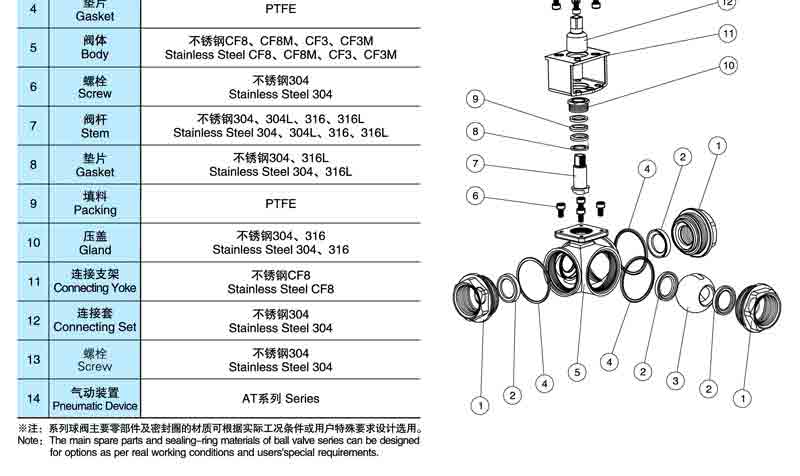

Pneumatic Internal Thread Three-Way Ball Valve Q614F/Q615F (Figure 7)

Optional Accessories

1. On/Off Control Accessories:

Single solenoid valve

Double solenoid valve

Limit switch with position transmitter

2. Flow Regulation Accessories:

Electric positioner

Pneumatic positioner

Electro-pneumatic converter

3. Air Supply Treatment Accessories:

Air filter regulator

Air supply triplet unit (filter + regulator + lubricator)

4. Manual Override:

Handwheel or lever actuator

Note: The L/T-type selection depends on flow distribution requirements, while accessories enhance automation, control precision, and operational flexibility.

Learn about the latest developments and updated designs of our products.

Submit an inquiry