Large caliber pneumatic fixed ball valve

Pneumatic Fixed Ball Valve (Large Diameter)OverviewThe O-type fixed ball valve...

Pneumatic Fixed Ball Valve (Large Diameter)OverviewThe O-type fixed ball valve...

Pneumatic Fixed Ball Valve (Large Diameter)

Overview

The O-type fixed ball valve features an upper and lower valve stem to secure the valve core (axle-supported) and a movable sealing seat design, ensuring more stable operation. With automatic compensation, bidirectional sealing, and a gap-free rotation that provides strong shear force and self-cleaning capabilities, it is particularly suitable for cutting off fibrous media, suspensions with fine solid particles, and viscous fluids. This product is widely used in automation control systems across industries such as papermaking, petrochemicals, chemicals, metallurgy, power generation, environmental protection, petroleum, and light industry.

Features

The O-type fixed ball valve adopts a fixed ball design, with friction-resistant self-lubricating materials in moving parts, ensuring low operating torque. Long-term sealing grease further enhances flexibility.

The high-platform structure complies with the ISO 5211 standard, enabling professional installation of electric/pneumatic actuators.

Available in full-bore or reduced-bore designs, minimizing flow resistance.

The metal hard-sealed O-type fixed ball valve features a bidirectional movable metal sealing structure with automatic compensation and self-cleaning, delivering superior sealing performance.

The fixed ball design incorporates preload springs, providing automatic pressure relief.

Each ball valve has two movable sealing seats, enabling bidirectional sealing and eliminating flow direction concerns during installation.

Fire-safe and anti-static design, with conductive springs between the valve stem, body, and ball to prevent static ignition of flammable media, ensuring system safety.

Double fire-safe protection: In case of fire damaging the seals, all sealing surfaces form a metal-to-metal hard seal.

Automatic pressure relief: If liquid media trapped in the valve cavity vaporizes due to temperature rise, the resulting pressure increase is relieved by the self-pushing action of the valve seat.

Optional pneumatic, electric, hydraulic, or regulating (pneumatic/electric) actuation. Refer to the actuator and control valve section for details.

Pneumatic Ball Valve

Overview

The pneumatic ball valve consists of a double (or single)-acting pneumatic piston actuator and a floating ball valve. Powered by compressed air, the valve stem rotates the ball 90° within the valve body. Available in soft-seal or metal-seal variants, it offers compact structure, small size, reliable performance, excellent sealing, and easy maintenance. It is widely used in industrial automation systems for petroleum, chemical, light industry, pharmaceutical, and papermaking applications.

Features & Applications

Pneumatic ball valves are primarily used to cut off or connect pipeline media and can also regulate fluid flow. Compared to other valve types, they offer the following advantages:

Low fluid resistance – Ball valves have the least flow resistance among valves, even in reduced-bore designs.

Thrust bearings reduce stem friction torque, ensuring smooth and flexible long-term operation.

Excellent seat sealing – PTFE (Teflon) or other elastic sealing rings provide reliable sealing, with sealing capability increasing under higher medium pressure.

Reliable stem sealing – The stem only rotates (no lifting motion), preventing seal damage. Sealing improves with rising medium pressure.

Long service life – PTFE’s self-lubricating properties minimize friction loss with the ball.

Blowout-proof stem – A bottom-mounted stem and stepped design prevent ejection. In case of fire damaging seals, metal-to-metal contact ensures stem integrity.

Anti-static function – Springs between the ball, stem, and body discharge static electricity generated during operation.

Working Principle

When the pneumatic actuator is connected to power and air supply, compressed air enters cylinder A (or B) via pipeline A/B, driving the piston and rotating the shaft and ball by 90°.

A visual indicator on the actuator shows valve position (green "Open" when activated).

Position feedback signals: Green light = Open; Red light = Closed.

A positioner allows flow regulation.

Technical Parameters of Pneumatic Actuator

| 气动执行器 | 型号 | QW系列、AT系列、AW系列 |

| 气源压力 | 0.4 ~ 0.8 MPa | |

| 最大回转角度 | 90°~92° | |

| 回信器 | AC220V AC110V DC24V | |

| 控制信号 | 电信号:0~0Ma 4 ~20Ma 气信号:0.02 ~0.1 MPa | |

| 控制气源 | 洁净、干燥压缩空气 | |

| 工作温度 | -20℃ ~ +90℃ |

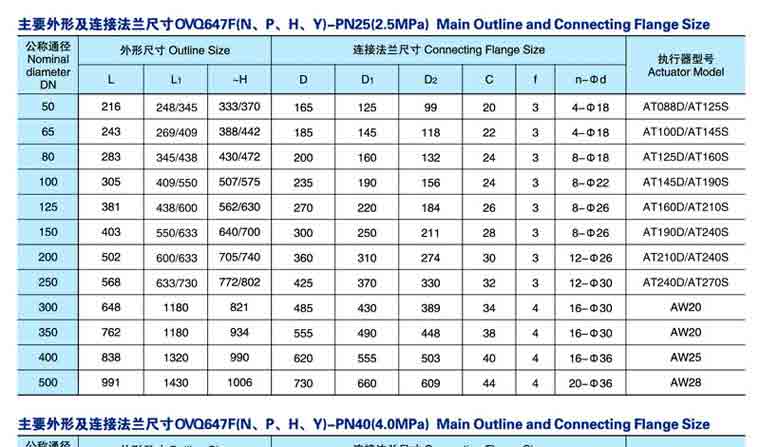

主要性能规范

| 型 号 | 公称压力PN(MPa) | 试验压力Ps(MPa) | 工作温度(℃) | 适用介质 | |

| 壳体 | 密封 | ||||

| Q641F/H-1.6 | 1.6 | 2.4 | 1.76 | -50~450(不同工况温度,选用不同的材质) | 水、石油、天然气、酸类等 |

| Q641F/H-2.5 | 2.5 | 3.75 | 2.75 | ||

| Q641F/H-4.0 | 4.0 | 6.0 | 4.4 | ||

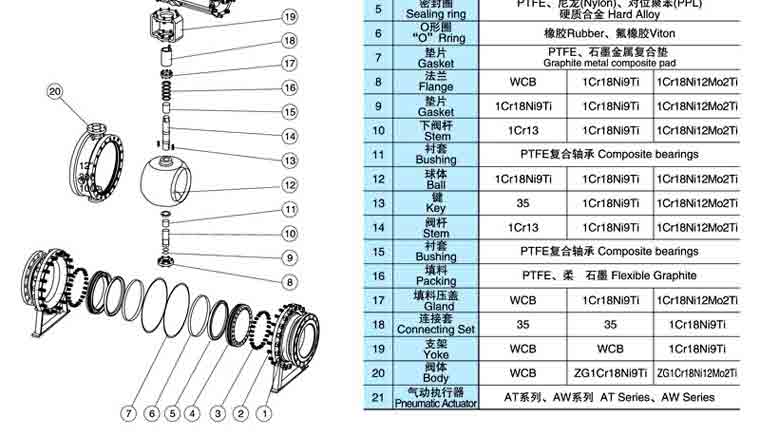

阀体主要零件材料

| 零件名称 | 阀体 | 球芯 | 阀座 | 阀杆 | 填料 | 支架 | 连接轴 |

| Q641F/H | 铸钢、不锈钢 | 不锈钢 | 聚四氟 | 2Cr13 | 柔性石墨 | 铸钢、不锈钢 | 铸钢 |

气动执行器主要部件材料

| 零件名称 | 缸体 | 端盖 | 活塞 | 轴 | O型圈 | 指示轴 | 螺栓 |

| QW系列AT系列 | 铝合金型材(硬质阳极氧化) | 压铸铝合金(环氧树脂喷涂) | 压铸铝 | 钢(镀镍磷合金) | NBR | ABC | SUS304 |

| AW系列 | 铸钢(硬质阳极氧化) | 压铸铝 | 钢(镀镍磷合金) | NBR | ABC | SUS304 |

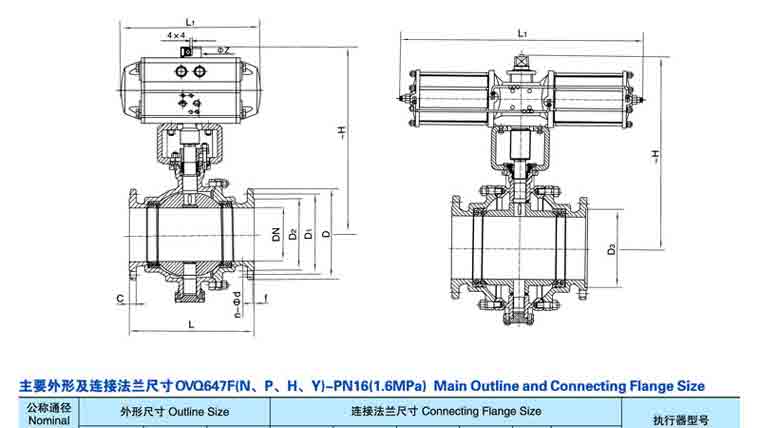

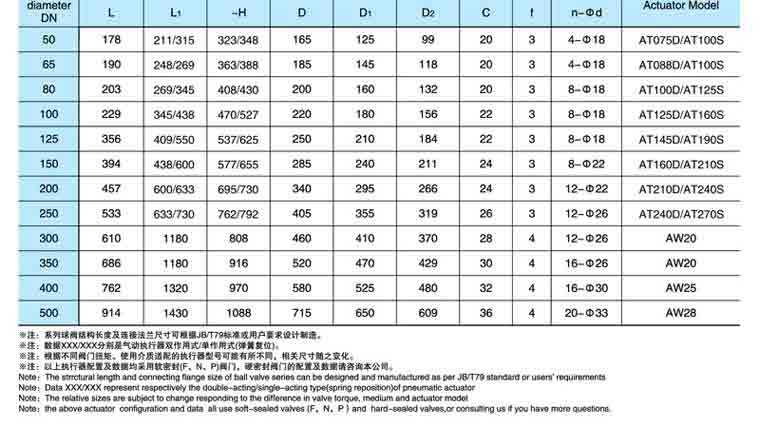

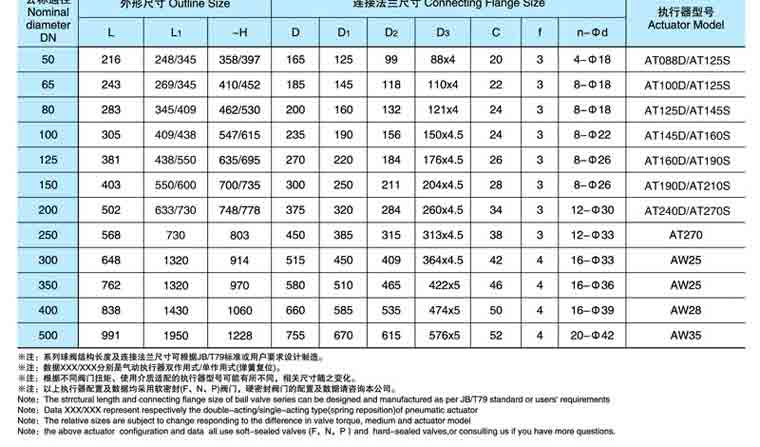

主要外形尺寸 (单位;mm)

| DN | L | H | D | D1 | L0 | Z-φd | 执行器型号 |

| 15 | 130 | 200 | 95 | 65 | 165 | 4-φ14 | QW01/AT50D |

| 20 | 140 | 204 | 105 | 75 | 165 | 4-φ14 | QW01/AT50D |

| 25 | 150 | 215 | 115 | 85 | 165 | 4-φ14 | QW01/AT63D |

| 32 | 165 | 240 | 135 | 100 | 225 | 4-φ18 | QW02/AT63D |

| 40 | 180 | 265 | 145 | 110 | 225 | 4-φ18 | QW02/AT75D |

| 50 | 200 | 275 | 160 | 125 | 225 | 4-φ18 | QW02/AT75D |

| 65 | 220 | 379 | 180 | 145 | 245 | 4-φ14/4-φ18 | QW03/AT88D |

| 80 | 250 | 390 | 195 | 160 | 330 | 8-φ18 | QW04/AT100D |

| 100 | 280/320 | 416 | 215/230 | 180/190 | 330 | 8-φ18/8-φ23 | QW04/AT115D |

| 125 | 320/381 | 542 | 245/270 | 210/220 | 380 | 8-φ18/8-φ25 | QW05/AT145D |

| 150 | 360/400 | 572 | 280/300 | 240/250 | 380 | 8-φ23/8-φ25 | QW06/AT160D |

| 200 | 400/500 | 736 | 335/360 | 295/310 | 440 | 12-φ25/12-φ25 | AW17 |

| 250 | 530/568 | 926 | 405/425 | 355/370 | 580 | 12-φ25/12-φ30 | AW20 |

| 300 | 600/648 | 1059 | 460/485 | 410/430 | 715 | 12-φ25/16-φ30 | AW28 |

| 350 | 550/762 | 1127 | 520/550 | 470/490 | 875 | 16-φ25/16-φ34 | AW28 |

| 400 | 600/838 | 1398 | 580/610 | 525/550 | 995 | 16-φ30/16-φ34 | AW35 |

附件的选项

根据不同控制和要求可选择下列附件:

切断型附件:单电控电磁阀、双电控电磁阀、限位开关回讯器。

调节型附件:电气定位器、气动定位器、电气转换器。

气源处理附件:空气过滤减压阀、气源处理三联件。

手动机构:手操机构

Learn about the latest developments and updated designs of our products.

Submit an inquiry